The Nori 1.68-ton hydraulic pulling truck stands ready for action in demanding environments — where power meets precision.

In the dim glow of dawn at a remote mining edge, where dust swirls around idling machinery and steel groans under tension, one machine commands respect not through noise, but through quiet dominance. It doesn’t just move loads — it redefines what’s possible when raw strength aligns with intelligent engineering. This is the world of the Genuine Nori 1.68-Ton 550 Wide Load Hydraulic Pulling Truck, a true powerhouse built not for spectacle, but for mission-critical performance.

Precision hydraulics and robust controls ensure seamless operation even under maximum load.

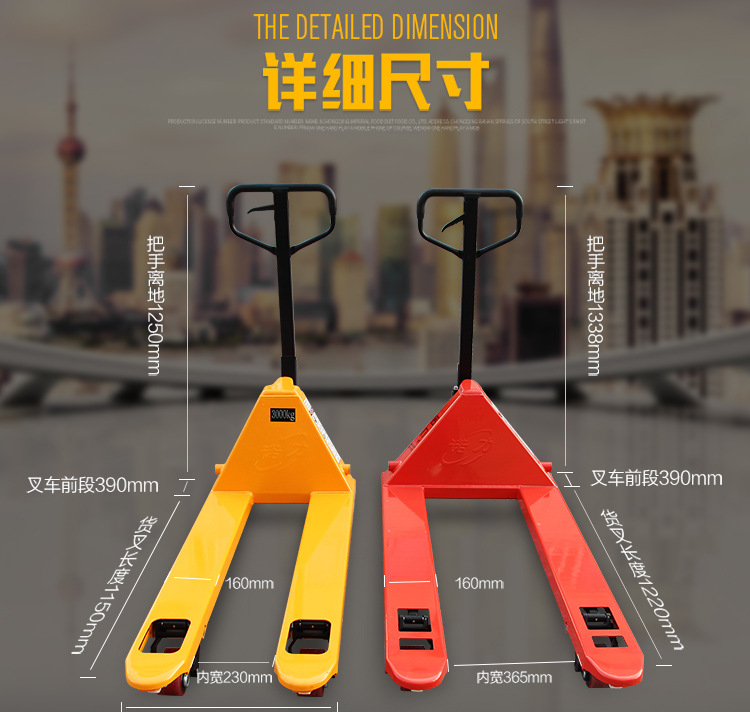

At first glance, this machine speaks a language of function over form — yet beneath its unassuming exterior lies an intricate dance of force and finesse. The 550mm ultra-wide loading platform isn’t merely about size; it's a declaration of stability. In high-tension scenarios where balance can mean the difference between success and catastrophe, the expanded footprint ensures minimal sway, optimal weight distribution, and unparalleled resistance to tipping — even on uneven ground or steep gradients.

But real power isn’t measured by brute force alone. What sets the Nori pulling truck apart is how it channels that force. Its advanced hydraulic system delivers consistent, controllable pulling energy, transforming explosive potential into smooth, calculated motion. Whether retracting a stalled excavator from muddy terrain or positioning multi-ton modules across offshore platforms, operators experience not just strength, but mastery — a sense that every ton pulled is done so with intent.

Reinforced alloy frame and rugged tires highlight structural integrity designed for longevity.

Beneath the surface, the Nori 1.68-ton model reveals its anatomy as a study in durability. Forged from high-strength alloy steel, the chassis resists torsional stress even during prolonged off-axis pulls. Dual-circuit hydraulic redundancy ensures operational continuity even if one line fails — a critical safeguard in isolated worksites far from immediate support. Meanwhile, integrated thermal management systems prevent brake fade during extended use, maintaining stopping power when it matters most.

Every detail has purpose: anti-slip deck textures, low-center-of-gravity design, sealed hydraulic joints resistant to dust and moisture — these aren't afterthoughts. They are responses to real-world challenges faced daily in tunnels, ports, and wind farms. One contractor recalls using the Nori unit to reposition a collapsed drilling rig inside a narrow tunnel bore — a task deemed too risky for conventional cranes. With precise inching control and stable anchoring, the job was completed in hours, not days.

Ergonomic interface and safety features empower operators to work confidently under pressure.

Safety here isn't bolted on — it's engineered in. Emergency pressure release valves, real-time load monitoring displays, and 360-degree visibility reduce risk before it emerges. These aren't luxuries; they're essential components of a machine designed for environments where failure isn't an option.

And while imitation models may offer lower upfront costs, they often compromise on material tolerances, seal longevity, and service accessibility. The Genuine Nori truck leverages factory-certified components and global technical support, ensuring years of reliable uptime. Over time, this translates to lower total cost of ownership — fewer breakdowns, less downtime, more trust.

Integrated into complex operations, the Nori pulling truck proves indispensable across industries.

Looking ahead, the future of heavy towing is smarter, more connected. The Nori platform already supports data output interfaces for remote diagnostics and usage analytics — paving the way for predictive maintenance and fleet integration. As job sites evolve, this machine evolves with them, bridging today’s demands with tomorrow’s innovations.

Hear from those who rely on it: Maria Lin, a site supervisor overseeing wind turbine logistics, says, “When we have to shift a tower section before sunrise, I don’t worry about whether the equipment will hold. I know the Nori will.” Another veteran operator shares how, during a midnight emergency recovery in a flooded quarry, the truck’s steady pull brought a submerged loader back online — three hours faster than estimated.

In an age obsessed with speed and disposability, the Genuine Nori 1.68-Ton 550 Wide Load Hydraulic Pulling Truck stands apart. It offers no shortcuts. No illusions. Just unwavering dependability — the kind that lets engineers sleep soundly, knowing their most impossible moves are covered. When the load exceeds limits and the stakes won’t allow error, there’s only one answer: Nori.